LAMINATED GLASS

What is laminated glass?

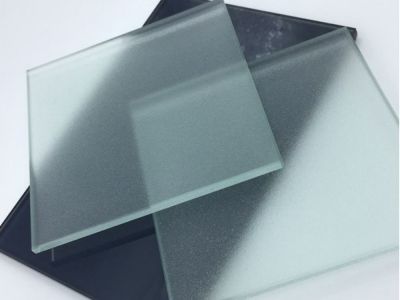

Laminated glass is made by permanently bonding two or more lites of glass together with a polymeric interlayer sheet using a process that involves exposure to cycles of heat and pressure within a specialized autoclave chamber. More than ever, laminated glass products are being used in various types of building construction applications serving as durable, translucent fenestration and building interior material options that offer the benefits of daylighting and unobstructed views while also meeting building code standard requirements for safety glazing applications.

APPLICATION

Laminated glass is a type of safety glass that is widely used in windows and doors, curtain walls of shopping malls and bathrooms; large glass walls, interior doors, decorative partitions, etc.

Laminated Glass with PVB Interlayer

PRODUCT FEATURES

Increased security: The strength of laminated glass make it almost impossible to break, so any unauthorised person would struggle to gain entry. Even if a break was to occur, the interlayers holdup the strength of the structure so that widening the gap is extremely difficult to do.

Reduced emissions: Low-emissivity glass can help to reduce heat gain from the sun, which allows air conditioning to be used less frequently and emissions to be reduced.

Reduced noise pollution: Installing a thick piece of laminated glass causes noise waves to become disrupted when they travel through the material, helping to reduce noise pollution.

Increased safety: As the glass doesn't shatter when broken, there is a reduced risk of someone being cut or injured by shards of glass.

Protection from natural disasters: In the arrival of natural disasters or volatile weather, laminated glass will remain in its frame, reducing the risk of accidents and making a life-threatening situation slightly safer.